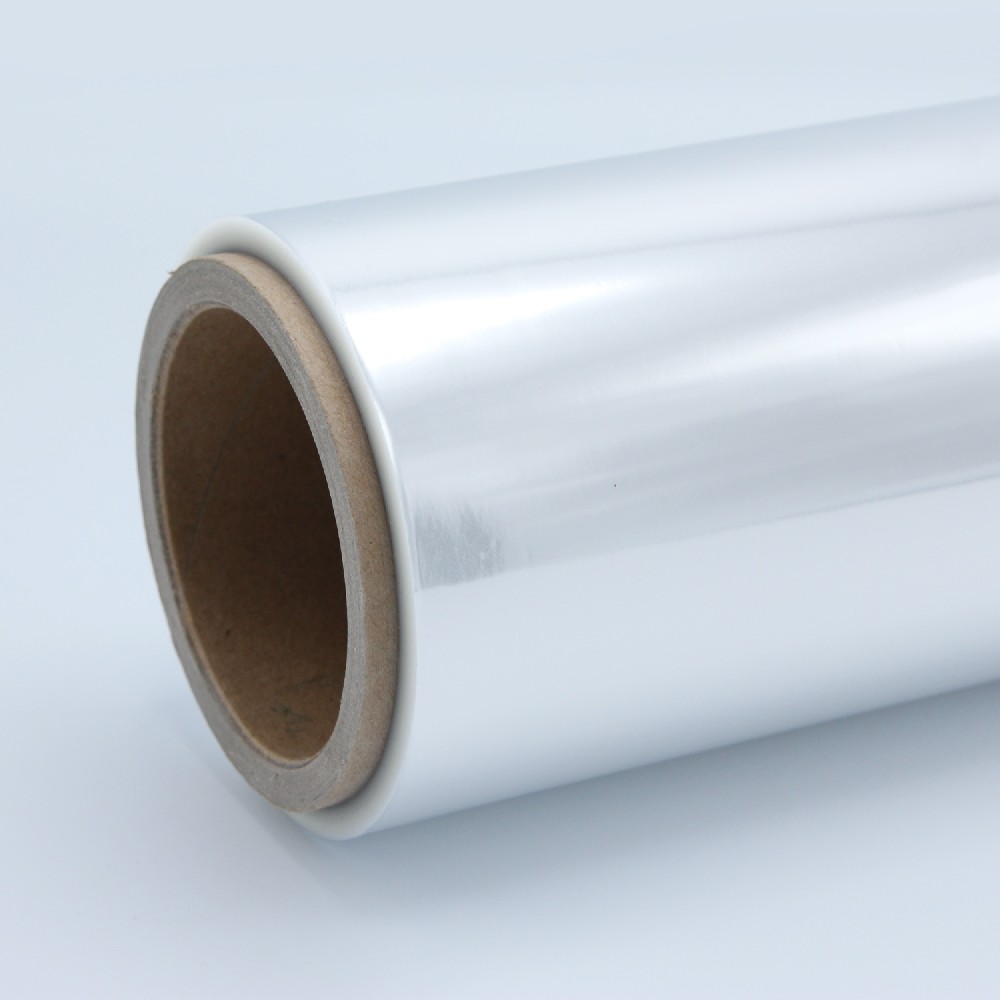

Effect of PET film on lamination

PET film has excellent barrier property and strong anti leakage property, so it is difficult for adhesive molecules to penetrate. Compared with ink, it has poorer absorption of glue molecules. Therefore, if the PET film is not surface treated, the adhesive layer will often separate from the film after laminating.

In order to enhance the adhesive strength between glue and PET, the PET film must be corona treated, that is, the surface of the film is roughened by high-frequency high voltage, and its wettability to the solvent is increased

PET film is stretched during the production process, and its resilience is very low. Therefore, when there is a deformation process after laminating, such as die-cutting, concavoconvex, embossing, etc., after the film is forcibly stretched again, the resilience force is higher than other films, and the thicker the film, the greater the resilience force. At the same time, because the paper and film are stretched in the deformation area, the adhesive layer will also be stretched and thinned, and the adhesive force will be reduced. Therefore, for the laminating film with this type of deformation, the amount of glue used cannot be too saved. For deeper deformation, a small sample shall be made first.

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Mobile:+8615169643109

Mobile:+8615169643109

Phone:+8615169643109

Phone:+8615169643109

Whatsapp:+8615169643109

Whatsapp:+8615169643109

Wechat:15169643109

Wechat:15169643109